Refinement

Visually? Haptic? or both? - You decide!

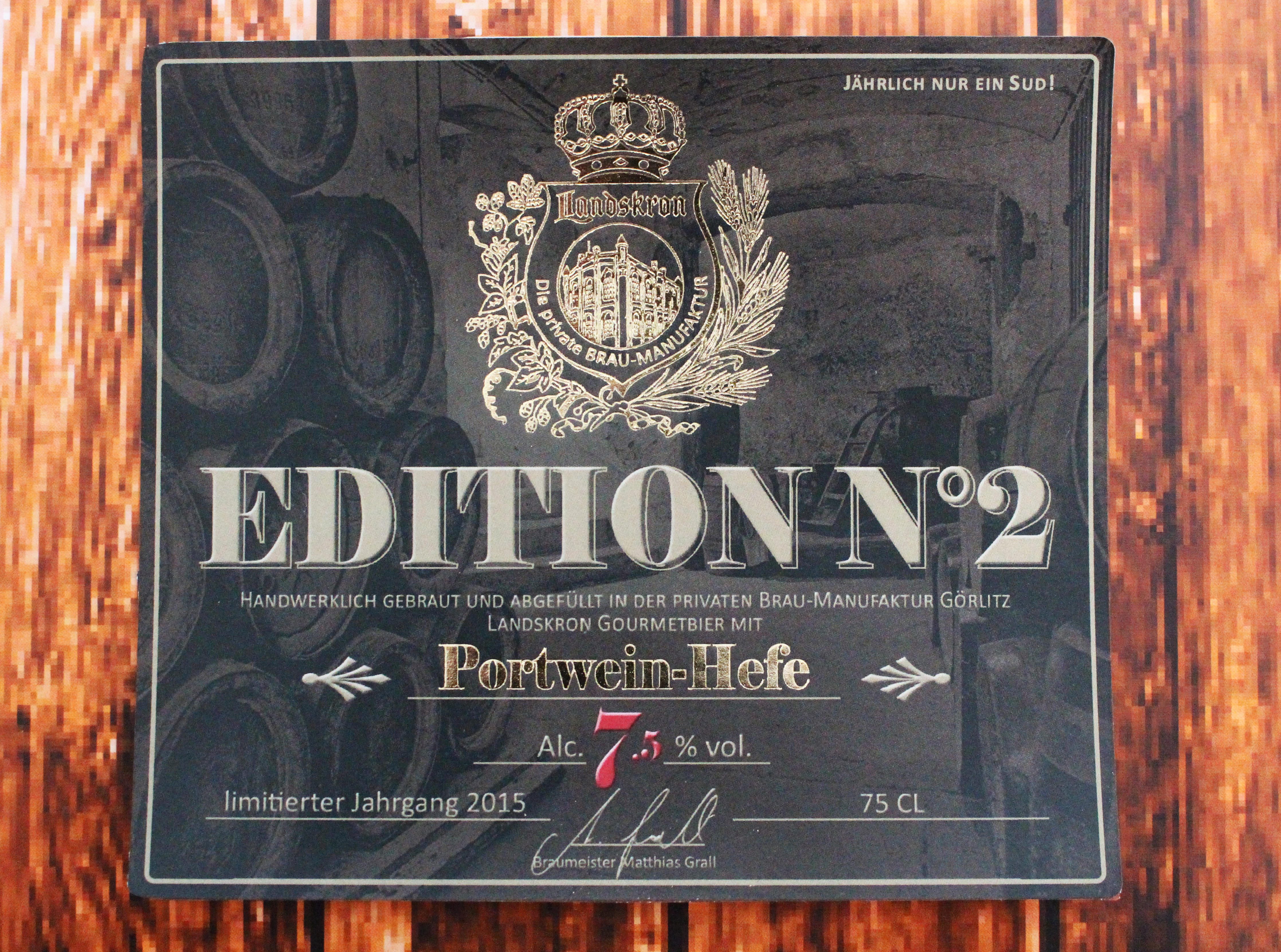

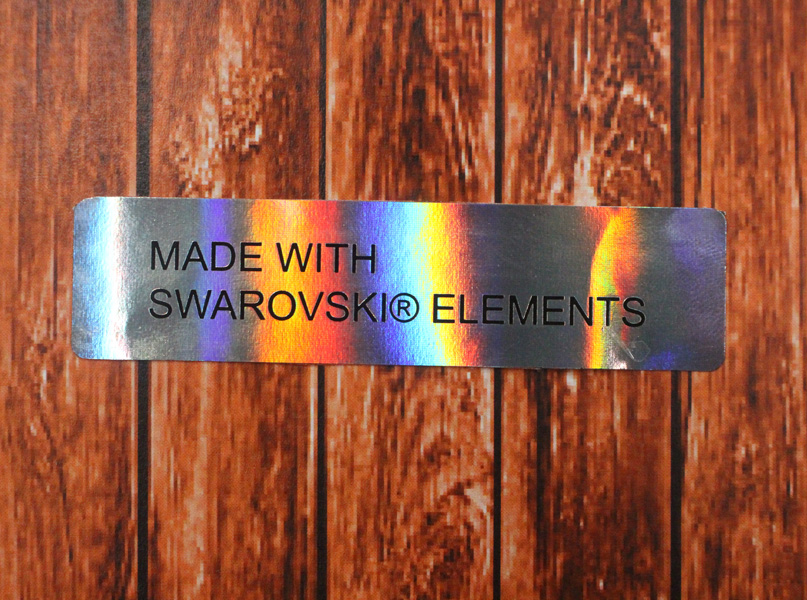

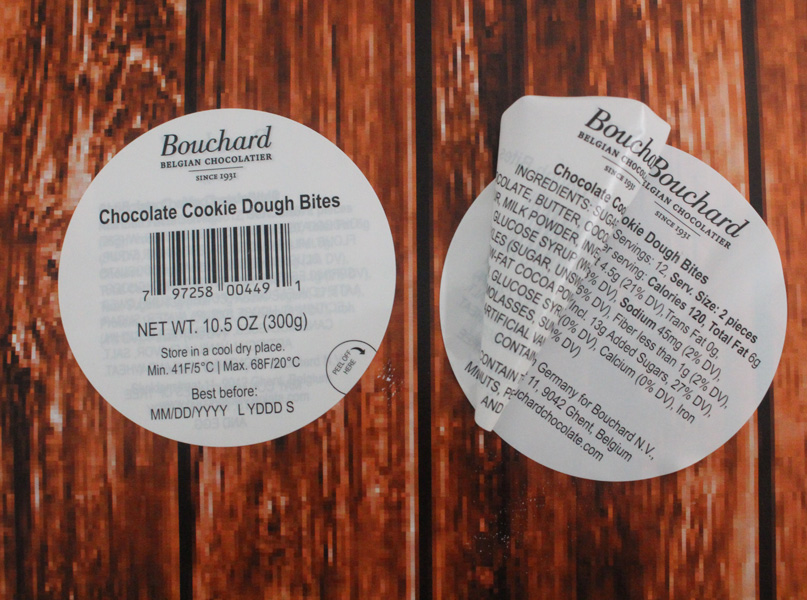

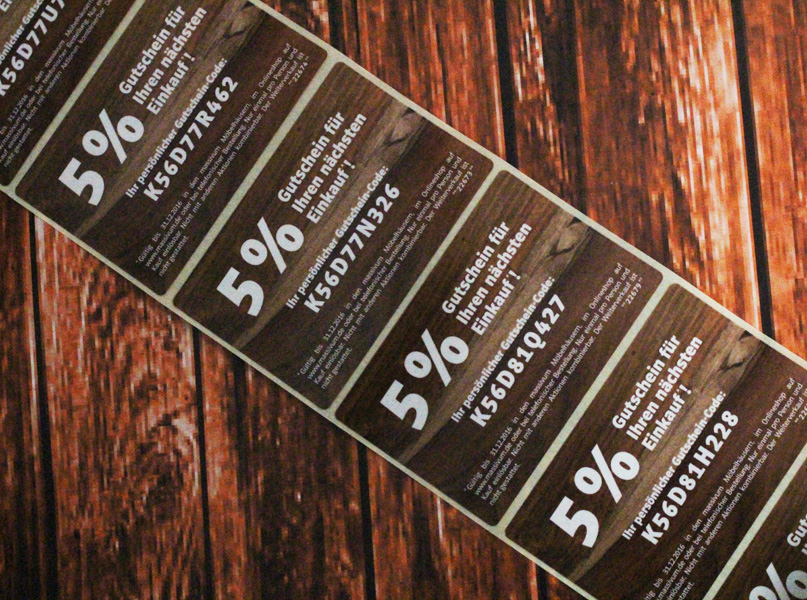

A refinement makes your product stand out from the crowd, magically attracts the consumer and remains in his memory.

With hot foil stamping, your adhesive label becomes a visual highlight.

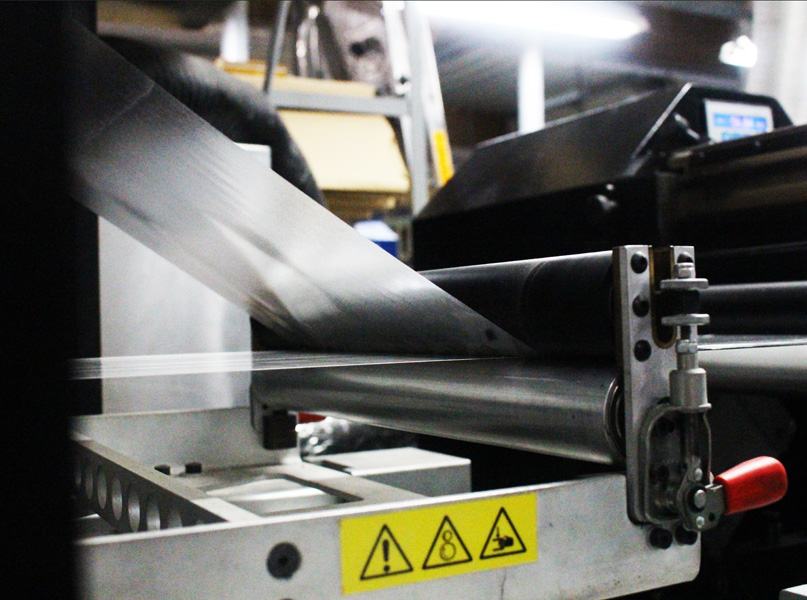

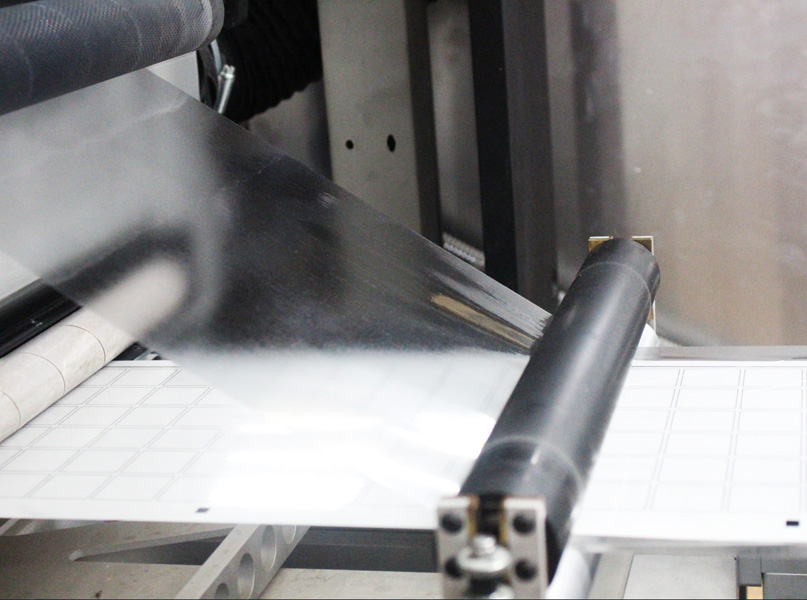

The labels are given a visual enhancement through varnishing or lamination and at the same time an additional surface protection.

Types of processing

Embossing (hot foil stamping) |

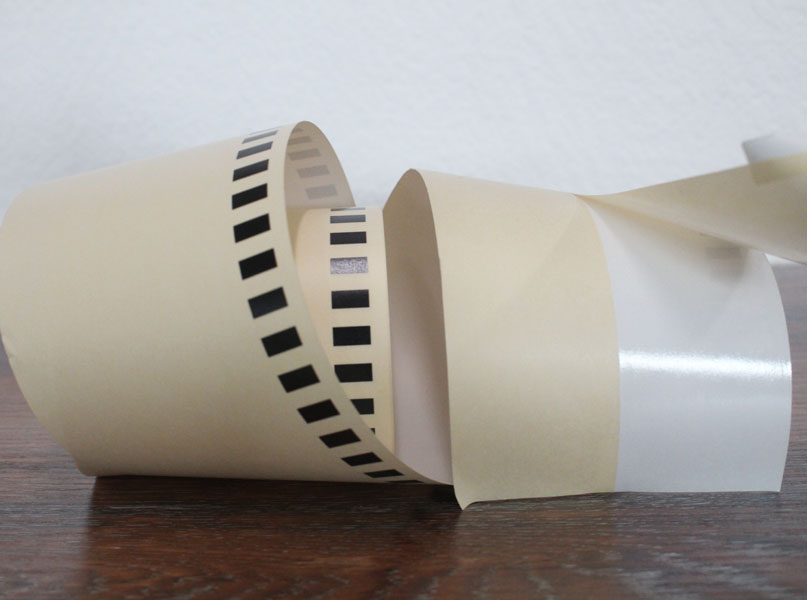

Lacquering |

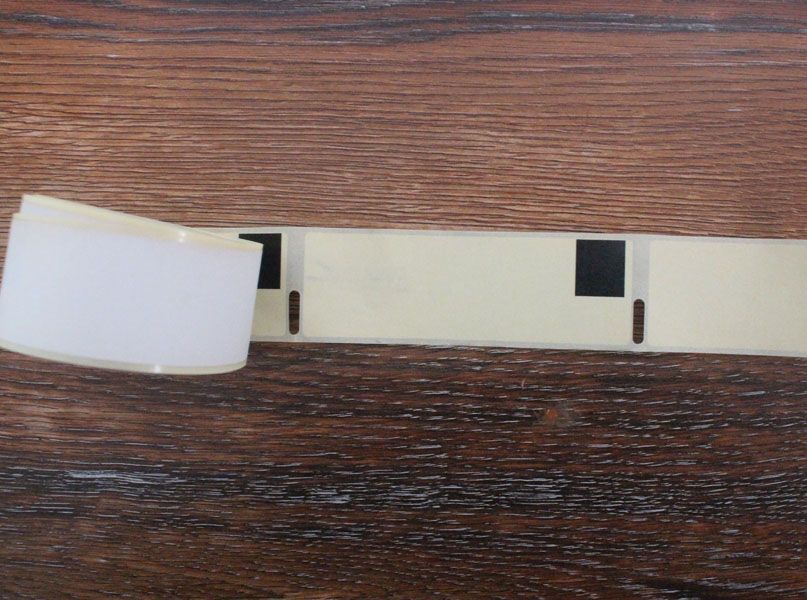

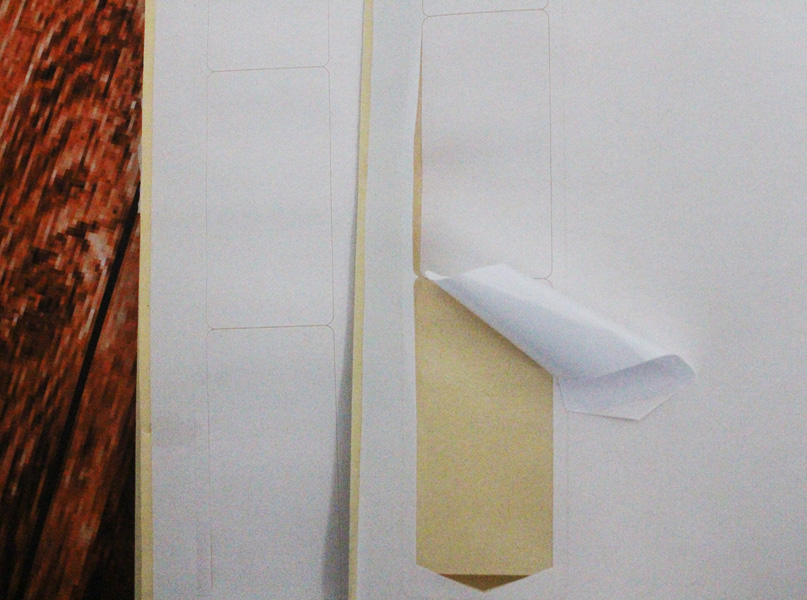

Lamination |

|---|---|---|

|

|

|