Presentation Types

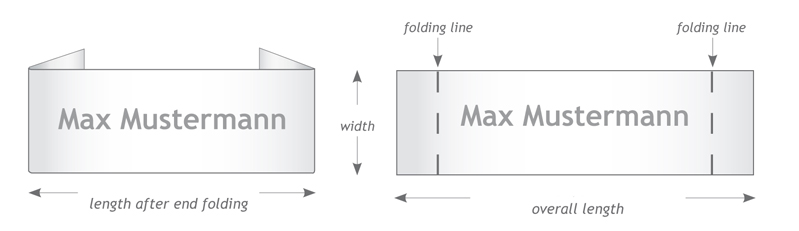

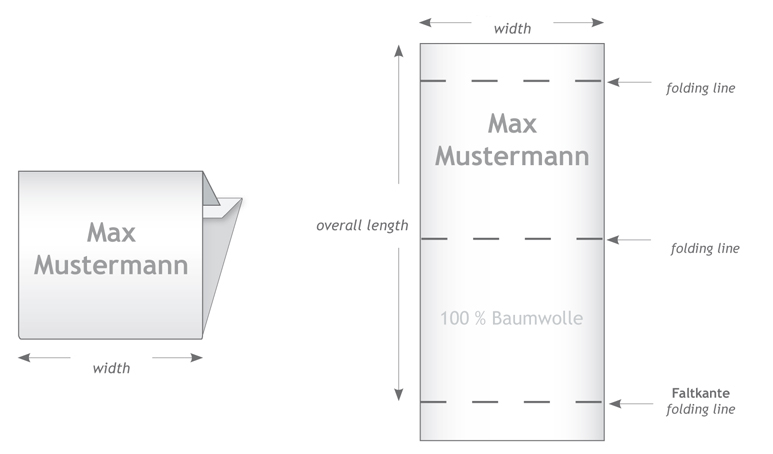

| Final Folding |  Application:

|

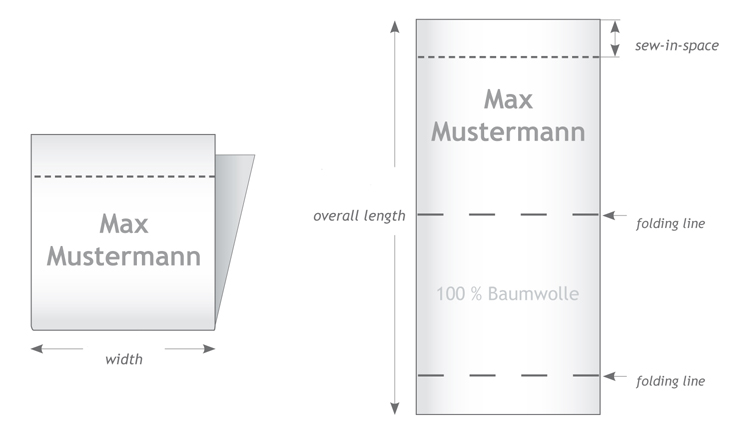

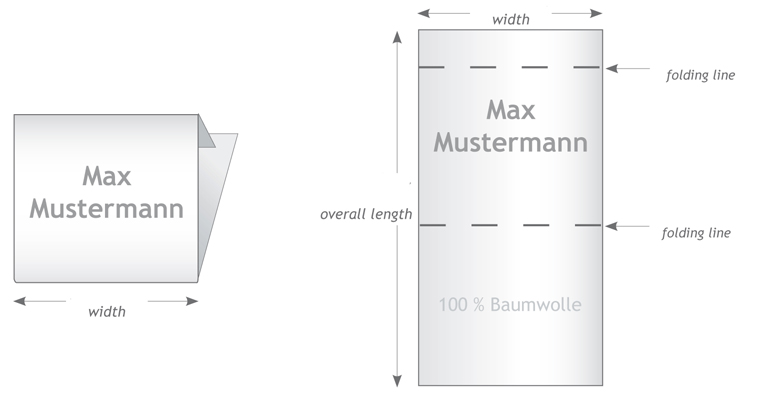

| Centrefolding |  Application:

Application:

|

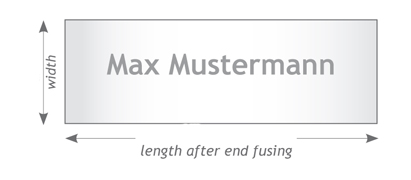

| Smooth Cut |  Application:

Application:

|

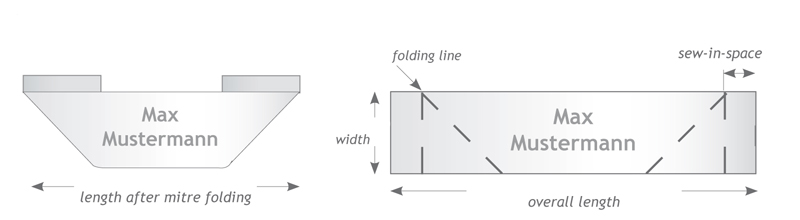

| Diagonal Folding |  Application:

Application:

|

| Booklet Unfolding |  Application:

Application:

|

| Manhattan Fold |  Application:

Application:

|

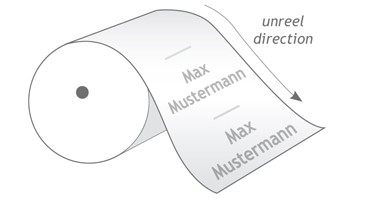

| Rolled |  |

Further common processes are laser cutting, laser engraving, zippers (also with filling), button bottles, overedging, embossing of motifs, reverse fleece or iron-on adhesive or HF welding adhesive coating, self-adhesive coating, centre fold with ends welded together, labels folded over on all sides, labels with firmly welded folds ...